Planetary Lab Powder Grinder

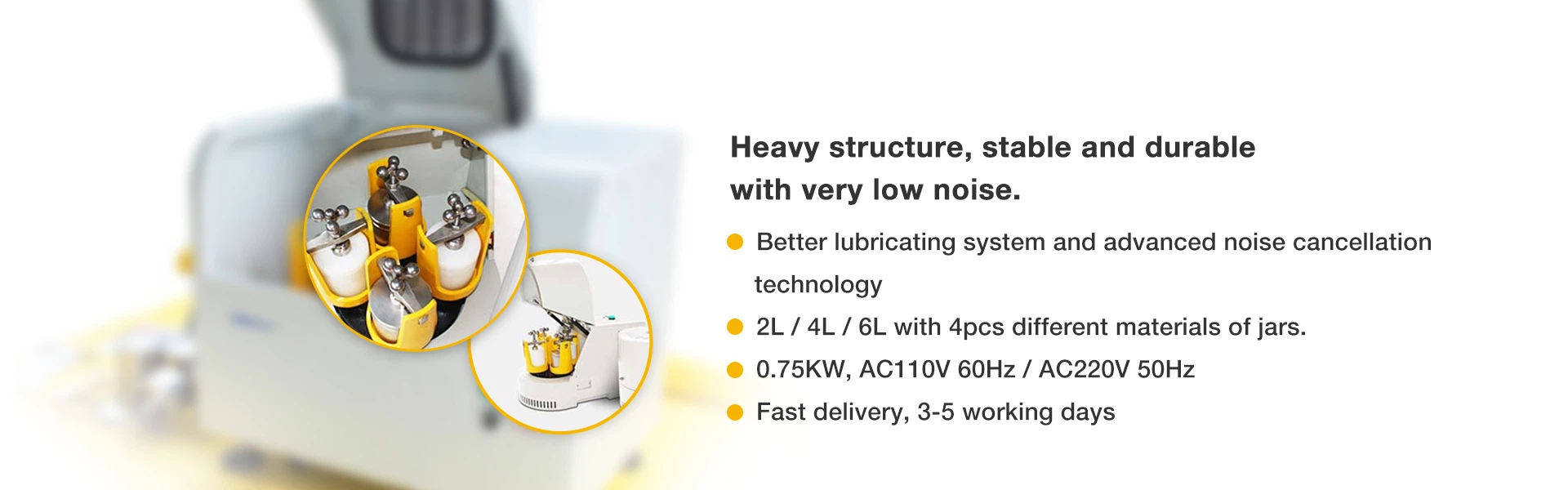

Planetary Ball Mills are designed for mixing, fine grinding, and preparing small volume high-tech material production. small volume,mini type high efficiency Most materials can be down to micron scale low noise

Description

Planetary Lab Powder Grinder

Planetary lab powder grinders are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of the Planetary Ball Mills result in very high pulverization energy and therefore short grinding times.

Minimum size of planetary ball mill discharge:

The minimum size of the discharge from a planetary ball mill depends on several factors, including the size and type of grinding media, the milling time, the rotational speed of the mill, and the properties of the material being milled. Achieving a specific minimum size can be challenging and may require optimization of these parameters.

In general, the grinding mechanism of a planetary ball mill can achieve particle sizes in the sub-micron to several microns range. However, reaching a specific minimum size, such as nanoparticles, typically requires additional techniques or processes, such as longer milling times, smaller grinding media, or the use of additives to facilitate particle size reduction.

The choice of grinding media can play a significant role in determining the minimum size of the discharge. Smaller and denser grinding media, such as zirconia or tungsten carbide beads, are often used for fine and ultra-fine grinding, enabling the production of smaller particle sizes.

It's important to note that achieving smaller particle sizes in the sub-micron or nano range may come with challenges such as increased heat generation, aggregation of particles, and potential contamination. Therefore, it is essential to carefully consider the material properties, milling conditions, and the specific requirements of the application when aiming for a minimum discharge size in a planetary ball mill.

Specifications:

Item No. | DECO-SG200 |

Compatible Grinding Jars | (50ml~100ml) * 2 |

Max Feeding Capacity | 2/3 capacity of the grinding jar |

Operation Mode | 2 grinding jars working simultaneously |

Jar material optional | 304stainless steel, PA,PTFE, Alumina ceramic, Zirconium ceramic, Agate, Tungsten carbide ,etc |

Feeding Granularity* | Soil materials < 10mm, others materials < 3mm |

Discharging Granularity(depend on materials) | Most material 2~10μm, for some materials down to 0.1μm |

Sample Type | hard, medium-hard, soft, brittle, moist, tough |

Rotational Speed of Grinding Jar | 900rpm |

Rotational Speed Ratio (planetary disk/jar) | 1 : 2 |

Drive Mode | gear drive and belt drive |

Speed Control | stepless speed regulation |

Electrical Details | 110V /220VAC, 50/60Hz, single phase, 0.25KW |

Net Weight/ Gross Weight | 38KG / 45KG |

Dimension (L*W*H) | 550*330*290mm |

We provide all kinds of mill pots in any matched size, which are made from 304 stainless steel, tungsten carbide, agate, PA nylon, PTFE, PU, zirconia ceramics, Alumina corundum ceramics,etc

Hot Tags: planetary lab powder grinder, China, manufacturers, suppliers, factory, price, principle, for sale