0.2L Mini Planetary Ball Mill For Lab Sample Test

This high quality planetary ball mill is widely used for powder and grinding of laboratory samples,exquisite workmanship, compact shape, stable performance.

Description

The Role of Small Planetary Ball Mills in the Laboratory:

Small planetary ball mills play a significant role in laboratory settings, offering several advantages and applications. Here are some key roles of small planetary ball mills in the laboratory:

Particle Size Reduction: Small planetary ball mills are utilized for efficient and controlled particle size reduction. They can grind and mill various materials to fine or even nanoscale sizes. This is particularly valuable for laboratories conducting research on materials with specific size requirements, such as nanoparticles or ultrafine powders.

Mixing and Homogenization: Planetary ball mills enable effective mixing and homogenization of different materials. The planetary motion of the grinding jars, combined with the high-speed rotation of the mill's central axis, promotes thorough mixing and blending of powders, pastes, suspensions, or liquids. This is crucial in achieving uniformity in composition and properties of samples.

Sample Preparation: Small planetary ball mills are widely used in sample preparation for various analytical techniques. They can grind, mix, and blend samples to create homogenous and representative specimens for subsequent analysis. This is beneficial for researchers working in fields such as materials science, chemistry, biology, and pharmaceuticals.

Material Research and Development: Small planetary ball mills are instrumental in material research and development activities. They allow scientists and researchers to study the effects of milling parameters, such as milling time, rotation speed, and grinding media, on different materials. This helps in optimizing processes, understanding material behavior, and exploring new formulations.

Quality Control and Testing: Small planetary ball mills play a role in quality control and testing procedures. They enable the production of consistent and reproducible samples for quality assurance purposes. Researchers can evaluate the impact of process variables on the final product quality, ensuring compliance with specifications and standards.

Scale-up Studies: Small planetary ball mills provide a platform for preliminary scale-up studies. Laboratory-scale experiments can help researchers understand the feasibility and performance of milling processes before transitioning to larger-scale production equipment. This aids in optimizing parameters, assessing scalability, and predicting outcomes.

Teaching and Education: Small planetary ball mills are valuable teaching tools in educational institutions. They allow students to gain hands-on experience with milling, grinding, and mixing processes. Students can learn about the effects of various parameters on material behavior and develop a deeper understanding of particle size reduction techniques.

Customization and Optimization: Small planetary ball mills offer flexibility and customization options. Researchers can choose from different jar sizes, grinding media, and milling parameters to tailor the process according to specific requirements. This allows for optimization of the milling process and customization for unique applications.

In summary, small planetary ball mills are versatile laboratory equipment that serve crucial roles in particle size reduction, mixing and homogenization, sample preparation, material research and development, quality control, scale-up studies, teaching, and customization. Their ability to provide controlled and efficient milling makes them valuable tools for scientists, researchers, and educators in a wide range of disciplines.

Features

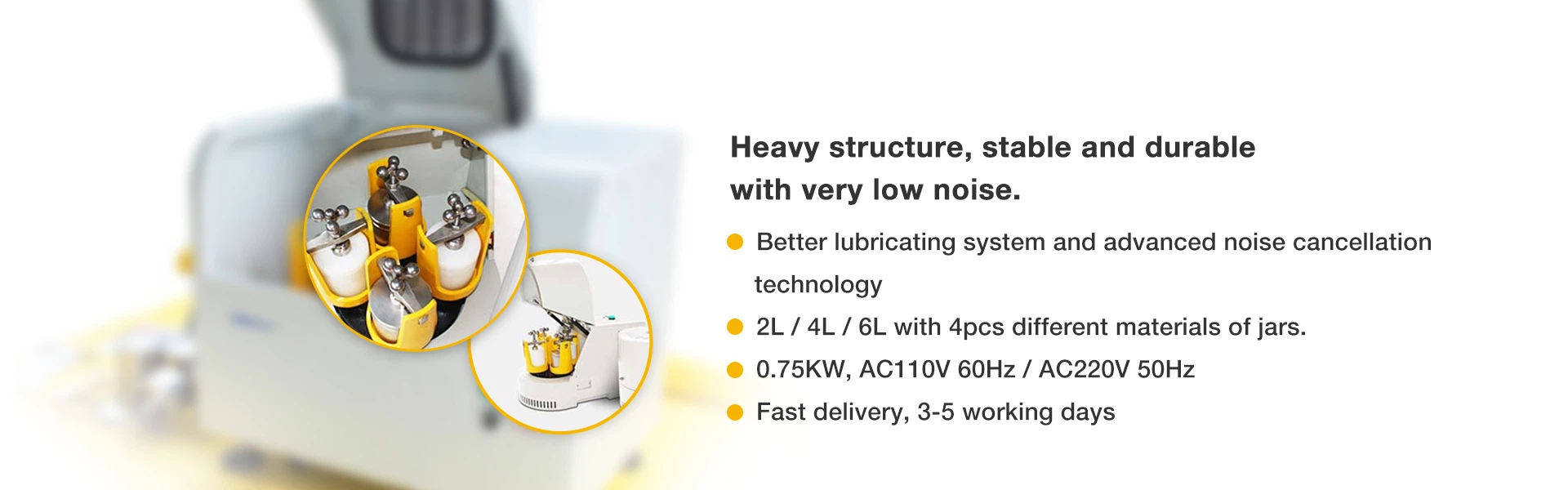

· Elegant design, easy to operate

· Ideal for wet or dry grinding application

· Automatic and programmable control with LED display

· multiple grinding modes to choose

· High Uniformity and excellent repeatability

· Fast rotational speed, high efficiency and fine granularity

· Four samples with different sizes and materials in one experiment

· Programmable interval and pause times

· Stepless speed regulation, reversing function

· Large range of materials available for grinding tools

· Gear-drive offers an effective solution to problems caused by belt driving

· Low center of gravity, good rigidity, compact structure, low noise, safe and reliable operation, no pollution and small wear

· Cooling of the grinding chamber with a built-in fan for long grinding times

Technical Data

Working Principle | impact and friction force |

Item No. | DECO-SG100 |

Compatible Grinding Jars | 50/100ml * 2 |

Max Feeding Capacity | 2/3 capacity of the grinding jar |

Operation Mode | 2 grinding jars working simultaneously |

Feeding Granularity* | Soil materials < 10mm, others materials < 3mm |

Discharging Granularity | down to 0.1μm |

Sample Type | hard, medium-hard, soft, fibrous, brittle, moist |

Rotational Speed of Grinding Jar | 900rpm |

Rotational Speed Ratio | 1 : -2 |

Drive Mode | gear drive and belt drive |

Speed Control | stepless speed regulation |

Electrical Details | 220VAC, 50Hz, 0.25KW |

Max Continuous Grinding Time | 72hours (full-load) |

Weight (Net /Gross) | 40KG /55KG |

Dimension (L*W*H) | 550*330*290mm |

Size of Planetary Disk | Dia190mm *T6mm |

Photo Show

How does a planetary mill work?

The planetary ball mill is composed of a planetary disk and two to four jar holders,when the planetary disk rotates, the jar holder rotates. under the force of rotation and revolution, the sample is grinding by the friction force and shear force generated by the grinding balls.

What is ball mill working principle?

Planetary ball mill has four ball grinding jar holders installed on one planetary disk. When the planetary disk rotates, the jar axis makes planetary movements and the balls in the jars grinds and mixes samples in high speed movement. The instrument can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of grinded products can be as small as 0.1 micron.

What are the balls in a ball mill made of?

The grinding ball has many materials, such as 304 stainless steel balls,zirconia balls,agate balls,PTFE balls,tungsten balls,alumina balls and so on.the selection of grinding ball material mainly depends on the material of the grinding tank and the nature of the sample,in general, it is recommended to select the same grinding ball material as the ball mill jar.

What are the types of ball mill?

There are three types of ball mills in common use: vertical, horizontal and all direction ball mill machine,vertical planetary ball mill for sample normal grinding,The horizontal ball mill is placed horizontally between the ball mill tank and the ground, which can effectively prevent the dead angle of the sample in the ball mill tank,The all direction ball mill is a product optimized on the basis of vertical and horizontal mills,Its planetary disk can be turned 360 degrees, making the sample more uniform, and greatly improving the grinding efficiency.

What is a ball mill used for?

Planetary ball mill is used to grind samples. It can grind some coarse particles into finer powder, even up to nanometer level,It is widely used in various industries,such as biological medicine, food, chemical industry, new energy, scientific research, etc

Hot Tags: 0.2l mini planetary ball mill for lab sample test, China, manufacturers, suppliers, factory, price, principle, for sale