40L Nanoparticle Planetary Ball Milling

40L nanoparticle planetary ball milling Introduction: Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to well-proven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy...

Description

40L nanoparticle planetary ball milling

Introduction:

Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to well-proven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying. The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times.

Application of planetary ball mill:

Depending on the fineness required, the grinding can be performed dry, in suspension or in inert gas. In addition to comminution, you can also use the mills for mixing and homogenising of emulsions and pastes or for mechanical alloying and activation in material research.

Technical Data

Specification

| Name | 40L nano particle planetary ball milling |

Model | DECO-PBM-AD-40L |

Capacity | 10 L *4PCS milling tanks |

Max feeding Capacity | 2/3 capacity of the milling tank |

Grinding ways | Dry grinding /wet grinding /vacuum grinding/low temperature grinding for optional |

Loading and unloading method | Intermittent type |

Transmission mode: | Gear drive and belt drive |

Control system | Frequency conversion control system, touch screen control system |

Rated voltage | 380 V-50Hz |

Rated power | 5.5 KW |

Rotation/ Revolution speed | 390rpm/ 195rpm |

Feed particle size(mm) | Soil material≤10mm, other materials≤3mm |

Discharge particle size(μm): | Most material 2-5μm, for some material like clay/graphene<1μm |

Ball mill material | Agate, zirconia, alumina ceramic, hard alloy, stainless steel, nylon, PTFE, PU |

Ball size(mm) | 3、5、8、10、15、20 |

Net Weight: | 1300KG |

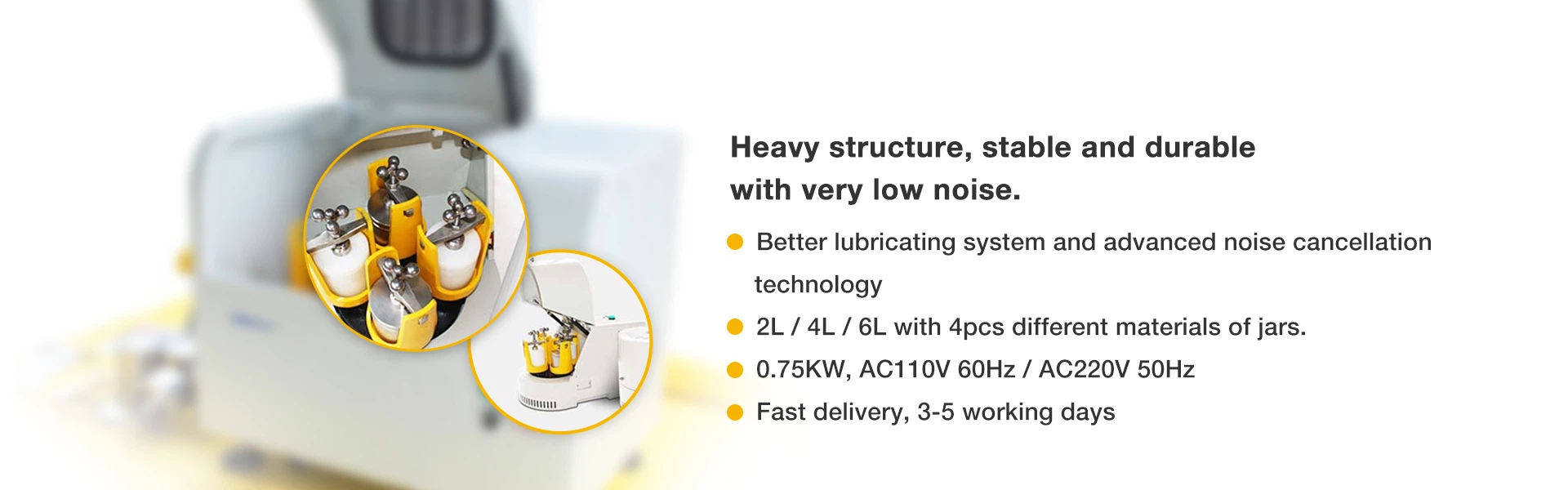

Features:

1.The machine makes 360 degree planetary movement without any dead corner, so the ground powder is much smaller and more even

2. It solves the problems of materials sinking and sticking to the pot.

3. Gear transmission ensures to keep consistency and repeatability of experiment.

4. You may get four different powder samples at one time.

5. Variable frequency controlled and program controlled.

Advantages

A wide range of powder can be ground by our planetary ball mill with different mill jars and balls, such as ore powder, fluorescent powder, glass powder, pigment powder and so on.

Packing:

Hot Tags: 40L nanoparticle planetary ball milling, China, manufacturers, suppliers, factory, price, principle, for sale