Lab Planetary Ball Mill For Grinding Samples

Brief introduction: The laboratory planetary ball mill is universally applicable for quick dry or wet grinding of inorganic and organic samples for analysis, quality control, materials testing and mechanical alloying. Working principle: The material is crushed and torn apart in two or four...

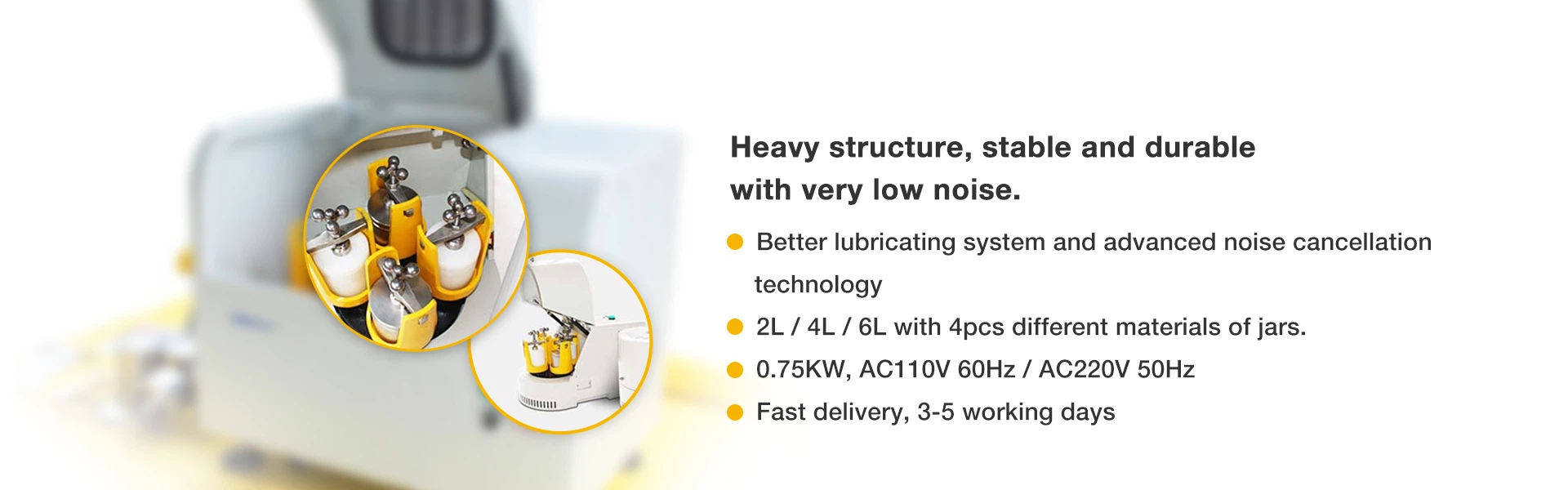

Description

Brief introduction:

The laboratory planetary ball mill is universally applicable for quick dry or wet grinding of inorganic and organic samples for analysis, quality control, materials testing and mechanical alloying.

What kind of sample is suitable for planetary ball mill grinding?

Planetary ball mills are versatile instruments that can be used for grinding a wide range of samples. The suitability of a sample for grinding in a planetary ball mill depends on several factors, including the sample type, its physical properties, and the desired end result. Here are some examples of sample types that are commonly suitable for planetary ball mill grinding:

Hard Materials: Planetary ball mills are excellent for grinding hard materials such as metals, alloys, ceramics, and minerals. These materials often require high-energy impacts for effective size reduction, and the intense grinding action of the balls in a planetary ball mill can achieve the desired results.

Soft Materials: Planetary ball mills can also handle soft or ductile materials that deform easily under mechanical forces. Examples include polymers, elastomers, rubber, and certain biological materials. In such cases, it's important to select suitable grinding parameters to prevent excessive heat generation and ensure gentle milling.

Brittle Materials: Brittle materials that are prone to fracture, such as glasses, brittle plastics, and certain crystalline materials, can be effectively ground in planetary ball mills. The high-energy impacts can induce cracks and fractures in the sample, leading to size reduction.

Pharmaceuticals and Natural Products: Planetary ball mills are commonly used in the pharmaceutical industry for grinding and homogenizing pharmaceutical ingredients, drug compounds, and natural products. The controlled grinding action allows for particle size reduction and mixing of different components.

Nanomaterials: Planetary ball mills are frequently employed for the synthesis and production of nanomaterials due to their ability to generate high-energy impacts and achieve fine particle sizes. They are used for processes such as mechanical alloying, nanoparticle synthesis, and dispersion of nanoscale additives.

It's worth noting that the specific sample size, shape, and composition can influence the grinding efficiency and results. Additionally, factors such as the milling time, rotation speed, and the ratio of grinding balls to sample also play a role in achieving the desired grinding outcome. Therefore, it's important to optimize the milling parameters based on the specific sample and desired result.

Working principle:

The material is crushed and torn apart in two or four grinding jars by grinding balls. The grinding balls and the material in the grinding jar are acted upon by the centrifugal forces due to the rotation of the grinding jar about its own axis and due to the rotating planetary disk.

The grinding jar and the planetary disk rotate in opposite directions, so that the centrifugal forces alternately act in the same and opposite directions.

This results in, as a frictional effect, the grinding balls running along the inner wall of the jar, and as an impact effect, the balls impacting against the opposite wall of the grinding jar.

The impact effect is enhanced by the grinding balls impacting against one another.

Loss-free grinding, even in the case of grinding of suspensions, is guaranteed by a hermetic seal between the grinding jar and the cover.

Electrical Details:

Single-phase alternating voltage 220-240V/ 110V-120V

The maximum power consumption is approx.: 250W

Material:

Max Feeding Capacity: 2/3 capacity of the grinding jar

Maximum feed size in the case of hard material approx. 10 mm

Achievable mean final fineness (depending on material) down to d50 < 1 μm

Grinding Speed:

Revolution (Grinding Speed of Planetary Disk): 550rpm

Rotation (Grinding Speed of Ball Mill Jar): 1100rpm

Item No. | DECO-PBM-V-0.4L |

Compatible Non Vacuum Grinding Jars | (50ml~100ml) * 4 |

Compatible Vacuum Grinding Jars | 50ml *4, 50ml grinding jars only for vacuum |

Operation Mode | 2 or 4 grinding jars working simultaneously |

Feeding Granularity | Soil materials < 10mm, others materials < 3mm |

Discharging Granularity | For some material, down to 0.1μm |

Sample Type | hard, medium-hard, soft, fibrous, brittle, moist |

Rotational Speed of Grinding Jar | 1100rpm |

Rotational Speed Ratio (planetary disk/jar) | 1 : 2 |

Drive Mode | gear drive and belt drive |

Speed Control | stepless speed regulation |

Electrical Details | 220VAC, 50Hz, single phase, 0.25KW |

Max Continuous Grinding Time (full-load) | 72hours |

Weight (Net /Gross) | 30KG /40KG |

Dimension (L*W*H) | 502*300*298mm |

Package (L*W*H) | 610*370*370mm |

Hot Tags: lab planetary ball mill for grinding samples, China, manufacturers, suppliers, factory, price, principle, for sale