20L Lab Scale Ball Mill

20L lab scale ball mill lab jar ball mill introduction: lab jar ball mill is ultra-fine grinding, mixing equipment used by laboratory and small batch production. The machine has compact structure, easy operation, high efficiency, fine-grained uniform grinding, is preferred equipment for...

Description

20L lab scale ball mill

Introduction:

lab jar ball mill is ultra-fine grinding, mixing equipment used by laboratory and small batch production. The machine has compact structure, easy operation, high efficiency, fine-grained uniform grinding, is preferred equipment for research, teaching, testing and production. It can be widely used in electronic materials, magnetic materials, bio-pharmaceutical, ceramic glaze slurry, non-metallic minerals, new materials and other industries.

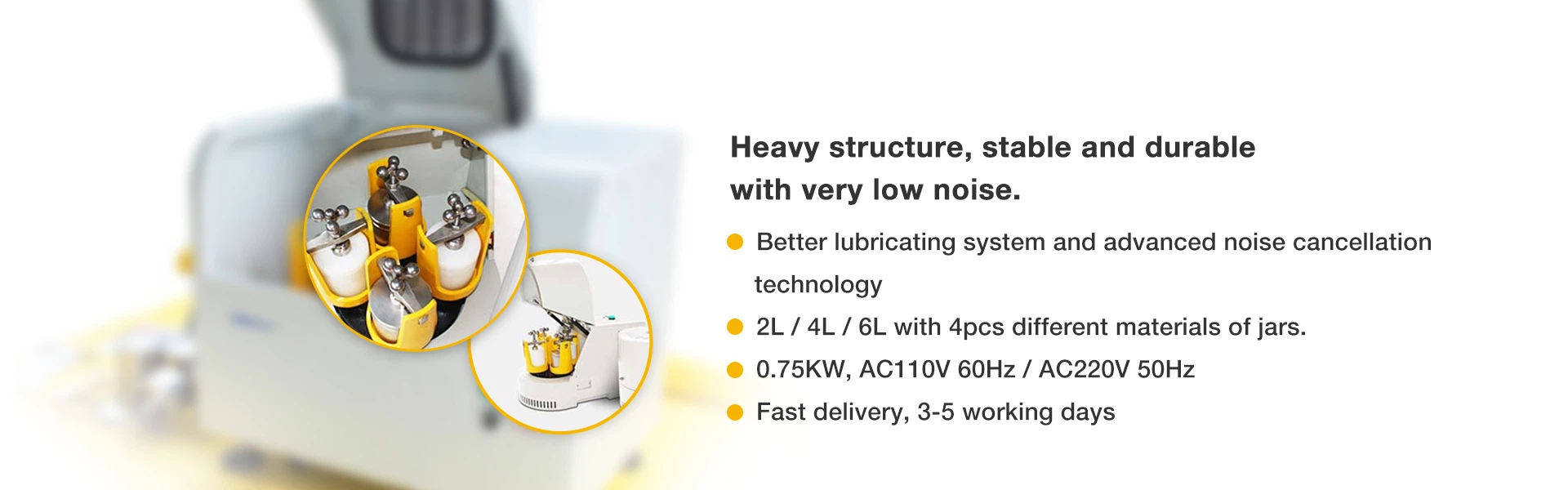

Features:

1. The structure of the machine is compact, easy to operate.

2. High working efficiency, uniform grinding fine-grained.

3. Can use different milling pot with different outside diameters within a certain range by adjusting the driven rubber roller.

4. Tanks changing is convenient. Suitable for both wet and dry grinding.

Specifications:

| Item No. | DECO-PM-4*5L |

Grinding Mode | Wet/Dry |

Structure | Single Tier |

Frame | Welded steel with PU coating |

Grinding Tools | Horizontal Grinding Jar |

No. of Grinding Jars | 4 |

Grinding Jar Volumes | 0.5L/1L/1.5L/2L/2.5L/3L/4L/5L or as requested |

Max Feed Size (depend on material) | 20mm |

Final Fineness (depend on material) | Most materials 300~400mesh, mini down to 15um |

Roller Rotational Speed | 380rpm |

Roller Length | 610mm |

Max Roller Spacing | 258mm (adjustable) |

Max Lateral Adjustment Spacing of Roller | 150mm |

Electrical Details | 220VAC, 50Hz ,0.75KW |

Overall Dimension | W860*D660*H660mm |

Dimension (Control Room) | W160*D660*H660mm |

Net Weight | 78KG |

Remark:

(1) Single tank, feeding grain size: ≤10MM diameter, output grain size: 15μm minimum diameter.

(2) Loading rate of ball mill can not exceed 70% of the effective volume of grinding cylinder.

Working Principle

While the lab ball mill starts working, the axises of machine starts to rotate and makes the jars on it rotating together rapidly. During jars motion, the material & milling balls inside jars ascend to certain height and then drop along the parabola whereabout by gravity. Eventually, materials inside it will be milled into powder by the repeated crushing with the balls & jar wall.

Varies materials of milling tanks

Products Details

With rich experiences of hard work in the industry, all kinds of lab ball mills we designed and produced have many advantages such as impact machine model, flexible and simple operation, grinding with dry and wet materials, which can meet requirements of dispersed grinding of all laboratories and further greatly benefit enlarging experimental results to production machine. The lab ball mills are the best choice for your labs grinding and research of new materials.

With sustained business conception of "Customer Is Superior, Quality Is in the First Position forever", we have gained a high reputation and good recognition from a lot of domestic and overseas customers such as Harvard University, Peking University, Tsingha University, Foxconn, BYD, CASC etc.

Hot Tags: 20L lab scale ball mill, China, manufacturers, suppliers, factory, price, principle, for sale