what is a ball mill jar

May 17, 2024

A ball mill jar, also known simply as a "jar," is a cylindrical container used in ball milling operations. It serves as the enclosure for the material being milled and the grinding media, such as balls or beads, in a ball mill. Ball mill jars come in various sizes and materials, depending on the specific requirements of the milling process and the nature of the materials being milled.

Key Features of a Ball Mill Jar:

Cylindrical Shape: Ball mill jars are typically cylindrical in shape, allowing for efficient rotation and movement of the milling media and materials inside.

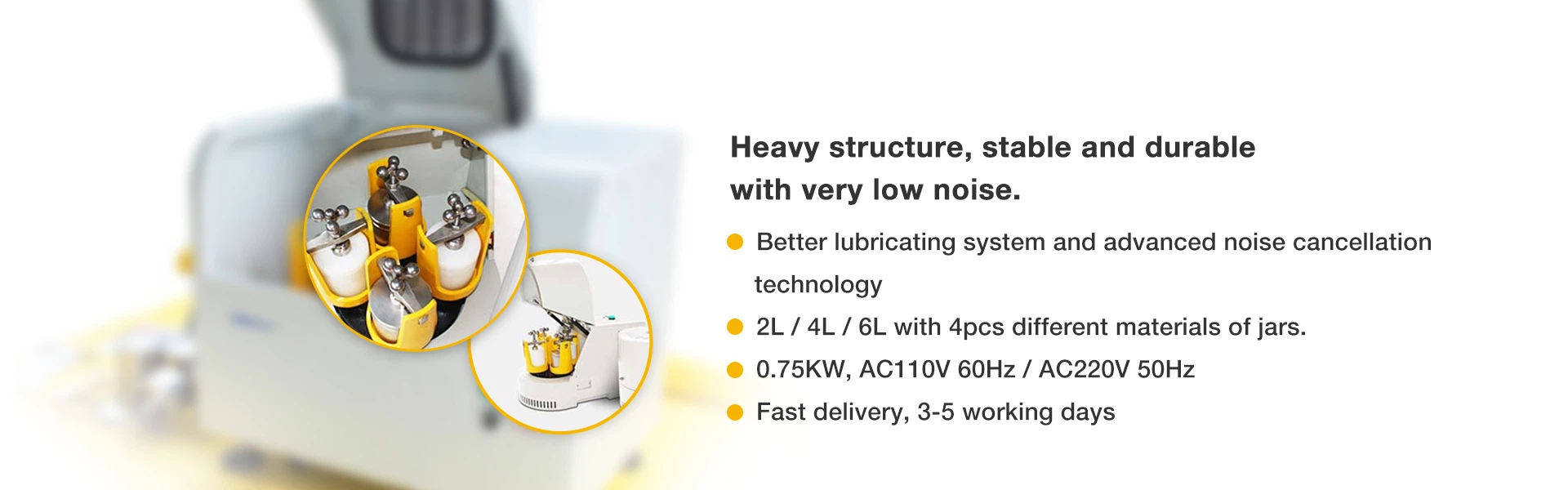

Materials: Ball mill jars can be made from a variety of materials, including stainless steel, alumina, zirconia, polyethylene, and glass. The choice of material depends on factors such as chemical compatibility, wear resistance, and the specific application requirements.

Lid: A lid or cover is typically attached to the top of the ball mill jar to seal the contents and prevent spillage or contamination during milling. The lid may have openings for ventilation or additional components, such as feed and discharge ports.

Sealing: Proper sealing of the ball mill jar is essential to prevent leakage and maintain a controlled environment during milling. This may involve using rubber gaskets, o-rings, or sealing compounds to ensure a tight seal between the jar and lid.

Capacity: Ball mill jars come in various sizes and capacities to accommodate different milling needs, ranging from small laboratory-scale jars to larger industrial-sized containers.

Functions of a Ball Mill Jar:

Containment: The primary function of a ball mill jar is to contain the material being milled and the grinding media, ensuring that the milling process occurs within a controlled environment.

Mixing and Blending: Ball mill jars facilitate mixing and blending of materials to achieve homogeneity or create composite materials with desired properties.

Grinding and Size Reduction: Ball mill jars enable the grinding and size reduction of materials through mechanical forces generated by the movement of the milling media inside the jar. This process results in the breaking down of particles into smaller sizes.

Particle Size Control: Ball mill jars allow for precise control over the particle size distribution of milled materials by adjusting milling parameters such as time, speed, and the size and type of grinding media.

Overall, a ball mill jar is a critical component of ball milling equipment, providing essential containment and processing capabilities for various milling operations in industries such as mining, ceramics, pharmaceuticals, and materials science.